Recent Projects

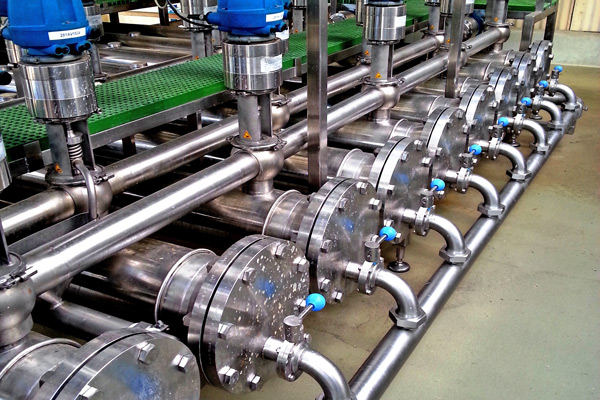

Farley Wastewater Treatment Facility Upgrade

- A major $70m upgrade to the Farley Wastewater Treatment Works to increase the capacity, cater for future growth and improve the reliability and performance of the plant.

- JC Butko was responsible for Structural, Mechanical, Piping and Fabrication Works within the Bioreactor, Blower System and Dewatering Facility – Stage 3B, including:

- Fabrication and installation of 43 access platforms and MBR operational deck all suspended 9m from the floor.

- Mechanical installation of all pumps, scum harvesters, membranes and blowers all withing tight tolerances.

- Fabrication and installation of all stainless steel process piping from 25NB to 1000NB with 10% NDT completed.

- Installation of all double contained chemical lines using the George Fishers CPVC piping system.

- Installations of all services piping including air to actuated valves and water to hose reels and safety showers.

- All works carried out in accordance with a project specific quality plan and individual ITP’s with full MDR’s issued on completion.

- JC Butko contributed part of the 500,000 site man hours with no MTI’s or LTIs.

Location: Farley, Maitland, NSW

Client: John Holland

Completion: 2021

Mount Buffalo viewing platform

- The Structure was Designed by Parks Victoria to replace an previously existing Lookout.

- The lookout is located in front of the Mt- Buffalo Chalet, adjacent to Bents Lookout.

- The Lookout is approximately 23m Long x 2.3m Wide, tapering to over 3.5m wide at the counter levered end.

- The Lookout is a full Steel Structure with painted finish and FRP Decking.

- The Main Glass Floor Panel which overhangs the rock face is 62mm thick Triple Laminated & Toughened Glass.

- The Glass Baluster Panels are 14mm thick Laminated & Toughened Glass

- The Handrail is made from polished Stainless Steel.

- The Lookout was designed to follow the natural rock formation and blend into the surrounding environment.

Location: Mt Buffalo, VIC

Client: Parks Victoria

Completion: 2021

Traralgon Hydrogen Plant

- World-first coal to hydrogen pilot plant – Project objective to convert brown coal into hydrogen gas.

- Japanese consortium backed by Federal & State funding.

- SMP Contractor for the Latrobe Valley Hydrogen Energy Supply Chain (LV HESC) Pilot Plant - Part of a $500 million Hydrogen Energy Supply Chain (HESC) project.

- JC Butko Scope of works:

- Construction of 6 level Coal Preparation Plant Building including installation of a Vertical Roller Mill, Bag Filter, Hot Gas Generator and all associated ducting, chutes and pipework.

- Construction of 3 level Gassification Building including a Gasifier and Pulse Jet Filter including all associated piping.

- Installation of all other Plant, including Gas Refining, H2 Compression and Storage, Flare System, Methane and Hydrogen Storage, Cooling Water Tower, Compressed Air, LPG Gas Supply, Steam Generating Plant inc. package boiler and Fire Water Ring Main and Supply System.

- Supply and erection of Pipe Bridges and Piping to connect all services.

- Approximately 70T of Structural Steel, in excess of 500 separate pipe lines installed, approximately 600 valves installed.

- Approximately 50,000 man hours

- Testing and Commissioning of all systems.

Location: Traralgon – Latrobe Valley

Client: J-Power

Completion: 2020

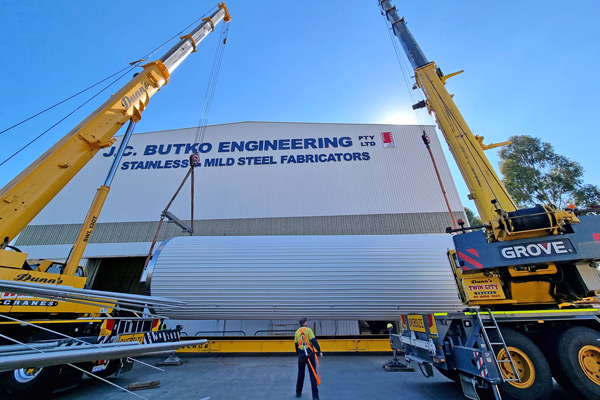

700,000 Litre Process Water Tank

- Fabrication and Installation.

- 304 S/S Tank.

- Fabricated in 4 sections with complete site assembly.

Location: Cowral, NSW

Client: Evolution Mining

Completion: 2021

75m3 Sugar Silo

- Fabrication, Insulation, Delivery and Installation of 75m3 sugar silo.

- 316 and 304 S/S material.

- Hygienic food-grade finish.

- Pneumatic blow lines and bin activator.

Location: Melbourne, VIC

Client: Fresco

Completion: 2021

Transport for NSW - Newcastle shared cyclist and pedestrian bridge

- The new single span bridge was transported to the Newcastle site as one assembly and is the first stage of the Newcastle Inner City Bypass Project. It is a shared cyclist and pedestrian bridge, improving safety and accessibility for pedestrians and cyclists.

- The bridge is a fully welded structure with painted finish, aluminium decorative baluster panels and stainless steel safety mesh.

- Dimension: 34m long x 4.1m wide x 5.0m high

- The top and bottom bridge chords are 400 x 300 fully fabricated box sections and are the main structural elements of the bridge.

- The bridge weighs approximately 40 tonnes.

- The bridge deck is concrete, poured in situ.

- The project also includes the installation of approximately 240 posts and decorative aluminium panels to access ramps and stairs with a fully continuous stainless steel hand railing.

- The project kept a team of ten busy for 9 months, with most works being undertaken during the COVID-19 lockdown period, requiring the Team to adapt to an ever-changing environment.

Location: Newcastle, NSW

Client: Transport for NSW

Completion: October 2020

Noreuil Park BBQ shelters

JC Butko Engineering was engaged to undertake Design assistance, Drafting, Fabrication, Painting, Delivery and Installation of 2 BBQ Shelters for Albury City Council. We were also responsible for overseeing all civil and concreting works whilst liaising with electrical and plumbing contractors. The shelter skeleton is fabricated from Mild Steel with 304 Grade polished Stainless Steel cladding.

Location: Noreuil Park Foreshore, Albury, NSW

Client: Albury City Council

Completion: May 2018

GrainCorp Oilseeds Refinery – Vegetable oil processor and tank farm

Design, Fabrication and Installation of 54 API650 Insulated and Heated Oil tanks with agitators up to 450KL, pipework and equipment including refiner and blending system.

Location: West Footscray and Numurkah, VIC

Client: GrainCorp

Contract Value: $18+ million

Completion: Current

Mars Petcare – Single Serve Upgrade

Fully Integrated Meat preparation, Tray filling, Cooking and Packaging line.

- Full design, fabrication, testing and installation of Meat de-palletizing, conveying, sorting and mustering equipment.

- Design and Installation of mixers, pigging systems, screw augers, hoppers and stainless steel pipework.

- Installation of ABB robotic loaders, retort cookers, platforms and walkways.

- Installation of packaging and palletizing equipment.

- Design and installation of steam and services piping systems.

- Commissioning and FAT support.

- Onsite construction management, Quality Systems and OH&S management.

Location: Wodonga, VIC

Client: Mars Petcare

Contract Value: $13+ million

Completion: 2018

Allied Mills Tamworth – Food Ingredients Plant Upgrade

Piping and Mechanical Works for Upgrade of Existing Manufacturing of Food Grade Products including Gluten, Starch, Dextrins and Caramel. Piping and Mechanical Works for installation of New Manufacturing Process to produce Food Grade Glucose.

- Installation of Free Issued Falling Film Evaporators and Hydrocyclones.

- Installation of Free Issued Ion Exchange Columns, Rotary Vacuum Filter, Pumps, Valves

- Heat Exchangers and Cooling Towers.

- Design and installation of steam and services piping systems.

- Design, Supply and installation of various Process Tanks and Systems.

- Fabrication, Supply and Installation of New Interconnection Pipework.

- Commissioning Support.

- Onsite management, Quality Systems and OH&S management.

Location: Tamworth, NSW

Client: Allied Mills

Contract Value: $5 million

Completion: 2017

Orora Paper WWTP Upgrade

Waste Water Treatment Plant Upgrade

- Design, Supply, Fabricate & Install 1-off 316 S/S Flocculation Tank.

- Design, Supply, Fabricate & Install 2-off 316 S/S Return Tanks.

- Design, Supply, Fabricate & Install 1-off 316 S/S Sludge Tank.

- Design, Supply, Fabricate & Install 2-off 316 S/S Rectangular Clarifier Tanks.

- Pipework Installation. Full Quality Assurance include Welder Traceability and NDT.

- Design, Supply & Install miscellaneous Access Platforms / Ladders.

- Installation of client supplied Pumps / Piping / Pipe Supports / Instruments / Chemical Dosing Equipment / Centrifuges and miscellaneous Plant and Equipment.

- Full onsite Project Management and site control including day to day operations.

- Final Plant Commissioning

Location: Botany, NSW

Client: Veolia Water Technologies

Contract Value: $2.9 million

Completion: 2017

Lend Lease – MRP Project

Explosives Plant

- Design, fabrication & Installation of 24 x 5.5m plus 2 x 6m diameter stainless steel storage tanks, associated pipework and access platforms

- Fabrication and installation of pipe rack steelwork and associated pipework for both Greenfield and Brownfield sites.

- Fabrication and installation of Chilled Water line (in excess of 3,000m of s/s piping)

- Providing a 24hr site maintenance team

- All welding in accordance with ASME 1X & minimum 10% radiographed

Location: Mulwala

Client: Lend Lease

Contract Value: $42 million

Completion: 2017

Terminals – Port Botany

Bitumen plant work

- 2 x 10,000m³ bitumen storage tanks - tanks are 26 metres wide and overall height of 21 metres

- 4 x 1,000m³ bitumen day tanks / 2 x 150m³ batching tanks

- 1 x 90m³ feed preheating tank and heat exchangers

- 2 x aeration towers & 2 x air compressors

- Associated insulated piping, pumping equipment and heat tracing systems

Location: Port Botany, NSW

Client: Terminals Pty Ltd

Contract Value: $6.5 million

Completion: 2015

Mars – Bathurst

Dryer Contract/Kibble Bin Contract/Piping and Processes contract

- All process and services piping, pump skids, valve trains and associated equipment

- Fabrication and installation of kibble bins, intermediate storage bins and hoppers

- Dryer installation

Location: Bathurst, NSW

Client: Mars Petcare

Contract Value: $3.5 million

Completion: 2015

Danone/Boccard – Kiewa

Yogurt Factory Upgrade

- Fabrication and installation of valve skids, and all associated process piping

- Supply and install of 25,000 litre food grade fermentation pressure tanks to 1.5BAR working pressure

- Supply and install of 25,000 litre batching tanks to atmospheric working pressure

- All works fabricated and installed to food grade specifications with all items passing through bacterial testing prior to commissioning

- Pipe spooling

- All tanks insulated and polished to Ra.8 finish

- Installation of client supplied product skids and onsite commissioning of the above works

- Onsite project management of 200 tonne crane for tank installation

- Ongoing 24hr maintenance breakdown servicing

Location: Kiewa, VIC

Client: Danone/Boccard

Contract Value: $4.0 million

Completion: 2015

Battery Recycling Facility – Installation

Renewed Metal Technologies (RMT) chose Wagga Wagga, NSW as its base to establish a lead recovery plant using the world’s best technology. The $55 million plant, which provides 55 jobs produces 25,000 tonnes of lead a year by processing 42,000 tonnes of used lead acid batteries – the batteries used in cars and other applications. As at Dec 12, The RMT site in Wagga is one of only five facilities in Australia with the capacity to recycle used lead acid batteries (ULAB).

- Installation of mechanical equipment tanks and steelwork supplied by an overseas company.

- Fabricate and install equipment support structures and access platforms, stairs and walkways in

accordance with Australian Standards. - Fabrication and installation of process and utilities piping. Coordination & project management of subcontractors (Electrical, Instrumentation, Insulation,

Scaffolding, Painting, Galvanising)

Location: Wagga, NSW

Client: Renewed Metal Technologies

Project Value: $55 million

Contract Value: $10.5 million

Commenced: Jul 2009

Completion: Feb 2010

Project Manager: Michael Butko

Nestle Tongala

Nutriceutical Project

Installation of a new Nutriceutical line

JC Butko Engineering was one of the key contractors involved with the $17m expansion at Nestlé’s Tongala factory in Regional Victoria. The Tongala factory in the state’s North-East, has been transformed into a state- of-the-art facility for Nestlé’s Health Sciences business as a manufacturing hub for Oceania, Asia, Middle East and Africa.

Following 18 months of construction work including rebuilding and refurbishing part of the existing site and installing new production lines, the factory now manufactures Nestlé Health Science’s hospital-grade ready to drink liquid supplements such as Resource, Isosource and tube feeding solutions for sick people who are unable to consume normal food.

- Fabrication and installation of Platforms and stairs and all process lines.

- Installation of supplied machinery including 6 tonne Scanima.

- Organization off all crane lifts and roof removal and reinstallation.

- All process lines were 316 S/S and purged welded from 20mm to 300mm tube.

- Fabrication and installation of 3 new ingredient hoppers and 2 smaller fluid tanks.

- Use of confined space to repairs of 3 existing product tanks.

Location: Tongala, VIC

Client: Nestle

Contract Value: $1.3 million

Commenced: Jun 2011

Completion: Sep 2011

Project Manager: Michael Butko and Mark Ellis

Gyprock Project – Plasterboard Line Design & Installation

JC Butko engineering were responsible for the fabrication and installation of the material handling and storage facility of raw and refined products at the CSR facility in Yarraville, Victoria.

Key responsibilities included:

- Fabrication of 8 conveyors (largest 200m long),

- Fabrication of various load hoppers

- Fabrication of 6m diameter storage hopper. JC Butko Engineering were also contracted to deliver items to site in Melbourne and supervise the installation of all items and produce the appropriate documentation.

Location: Yarraville, Melbourne, VIC

Client: CSR

Contract Value: $3 million

Commenced: 2008

Completion: 2009

Project Manager: Michael Butko

Macleay River Floodplain Bridge

The 3.2km high-level bridge spanning the river and floodplain is the longest operating road bridge in Australia. Initially, the scope comprised two separate twin-bridges totaling 2.45km in length. However, during post-contract negotiations the RTA increased the scope of the project to a longer, single bridge.

JC Butko Engineering’s contract scope involved the fabrication and supply of Barrier Rails, Bridge Bearing Plates, Formwork and S/S Drainage. All works were carried out in the Wodonga factory and transported to site for installation.

Location: Kempsey NSW

Client: Abigroup Contractors Pty Ltd.

Project Value: $185 million

Contract Value: $3.5m (Supply Barrier Rails and Bearing Plates)

Commenced: 2010

Completion: 2012

Project Manager: Alwyn Tonks

Contact Us

Postal Address

7 Moloney Drive

Wodonga VIC 3690

Australia

Email

enquiries@butko.com.au

Phone

(02) 6024 4799

International +61 2 6024 4799

Facsimile

(02) 6024 4075

International +61 2 6024 4075

© Copyright JC Butko Engineering Pty Ltd 2022

Site by Ian Cossor Design.